Feasibility Study and Cost Estimation of Vitamin C Supplement Manufacturing Plant: A Comprehensive Cost Model

What is Vitamin C Supplement?

Vitamin C supplements are typically made by extracting ascorbic acid from various sources, such as citrus fruits, or synthesizing it in a laboratory setting.

Key Applications Across Industries:

The extracted or synthesized ascorbic acid is then processed and formulated into different types of supplements, including tablets, capsules, chewable, and powdered forms. One of the primary advantages of Vitamin C supplements is their ability to support a healthy immune system. As a powerful antioxidant, it helps protect the body's cells from damage caused by free radicals, thereby enhancing the immune response against infections and illnesses.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global vitamin C supplement market was valued at US$ 1,423 Million in 2024, growing at a CAGR of 7.1% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 9.0% from 2025 to 2033, reaching a projected value of US$ 3,080 Million by 2033. Growing consumer health consciousness and understanding of the significance of vitamin C for immune support and general well-being have an impact on the global market for vitamin C supplements.

Additionally, the market is growing because of the increased use of preventive healthcare measures, such as vitamin C supplements, brought about by changing lifestyles and rising disposable incomes. Furthermore, the market is expanding due to the growing number of elderly people and the increased emphasis on anti-aging products. Moreover, as vitamin C deficiency is becoming more common in different areas, there is a growing need for supplements to fill up nutritional deficiencies, which is driving market expansion. Accordingly, the growth of the market is being aided by the development of e-commerce platforms and the accessibility of a large variety of goods. The market is expanding due to a number of other factors, including continuous research and development (R&D) efforts and advancements in formulations and delivery systems.

Case Study on Cost Model of Vitamin C Supplement Manufacturing Plant

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale vitamin C supplement manufacturing plant in Mexico.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with production capacity of 60 tons of vitamin C supplement per day.

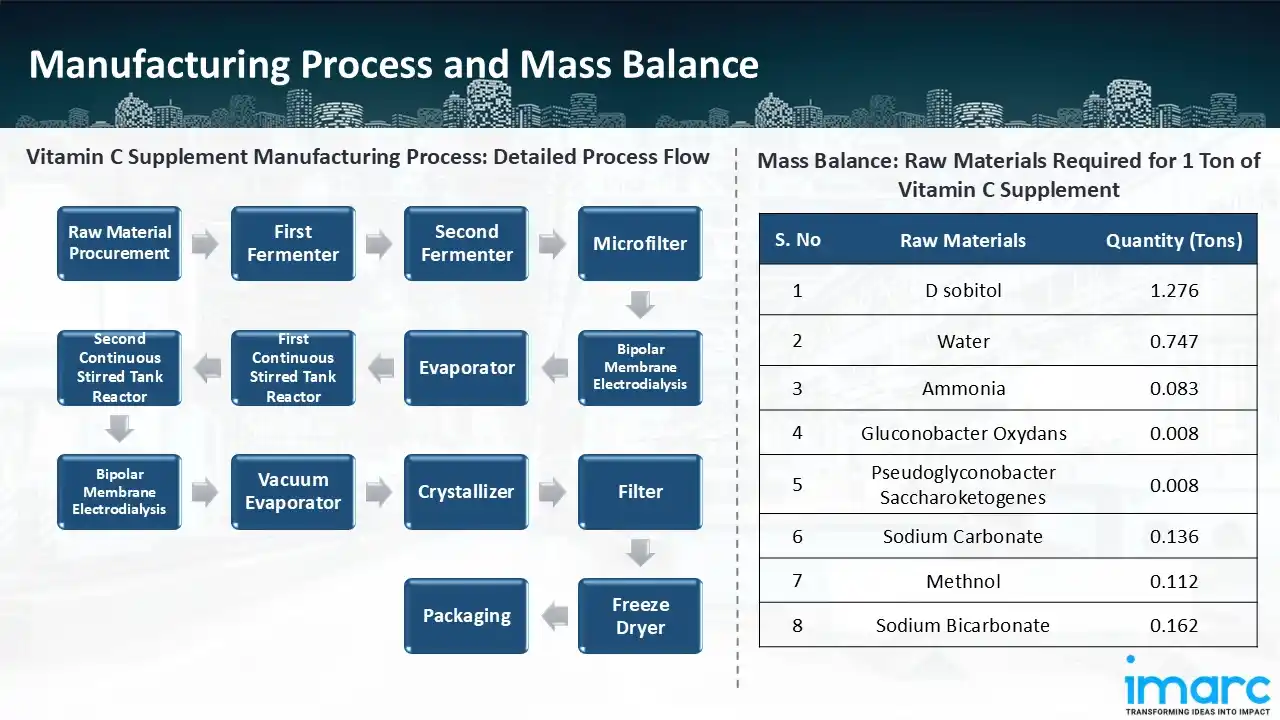

Manufacturing Process: The first step in making vitamin C supplements is obtaining raw materials, where vital minerals and carbohydrates are obtained as necessary components. The first fermenter is where the process begins, when microbes transform glucose into intermediate chemicals. The product is further refined as the fermentation proceeds in the second fermenter. To get rid of undesirable particles, the liquid is microfiltered after fermentation. Bipolar membrane electrodialysis, which aids in pH correction and impurity removal, is subsequently applied to the filtered solution. An evaporator is used to remove extra water from the concentrated solution. To improve the yield of vitamin C, the material next passes through the first and second continuous stirred tank reactors (CSTRs) for regulated chemical reactions. Following a second round of bipolar membrane electrodialysis for additional purification, moisture is extracted using a vacuum evaporator. Pure Vitamin C is separated from the remaining liquid by passing the solid crystals that are formed in the crystalliser through a filter. To preserve stability and increase shelf life, the extracted crystals are put through a freeze dryer. Lastly, the dried vitamin C is prepared for distribution by being packed into tablets, capsules, or powder. High-purity vitamin C supplements that satisfy industry standards are guaranteed by this methodical procedure.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the vitamin C supplement manufacturing plant include D sorbitol, water, ammonia, Gluconobacter Oxydans, Pseudoglyconobacter Saccharoketogenes, sodium carbonate, methnol and sodium bicarbonate. To manufacture 1 Ton of Vitamin C supplements, we require D-Sorbitol (1.276 Tons), Water (0.747 Ton), Ammonia (0.083 Ton), Gluconobacter Oxydans (0.008 Ton), Pseudoglyconobacter Saccharoketogenes (0.008 Ton), Sodium Carbonate (0.136 Ton), Methanol (0.112 Ton), and Sodium Bicarbonate (0.162 Ton).

List of Machinery:

The following equipment was required for the proposed plant:

- Fermenter

- Disc Centrifuge

- Microfiltration

- Bipolar Membrane Electrodialysis (BME)

- Thin Film Evaporators

- Continuous Stir Tank Reactor

- Crystallizer

- Freeze Dryer

- Automatic Sorting Machine

- Automatic Powder filling machine (with NPLsystem)

- Automatic capping machine

- Foil Filling Machine

- Labelling Machine

- Air compressor

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

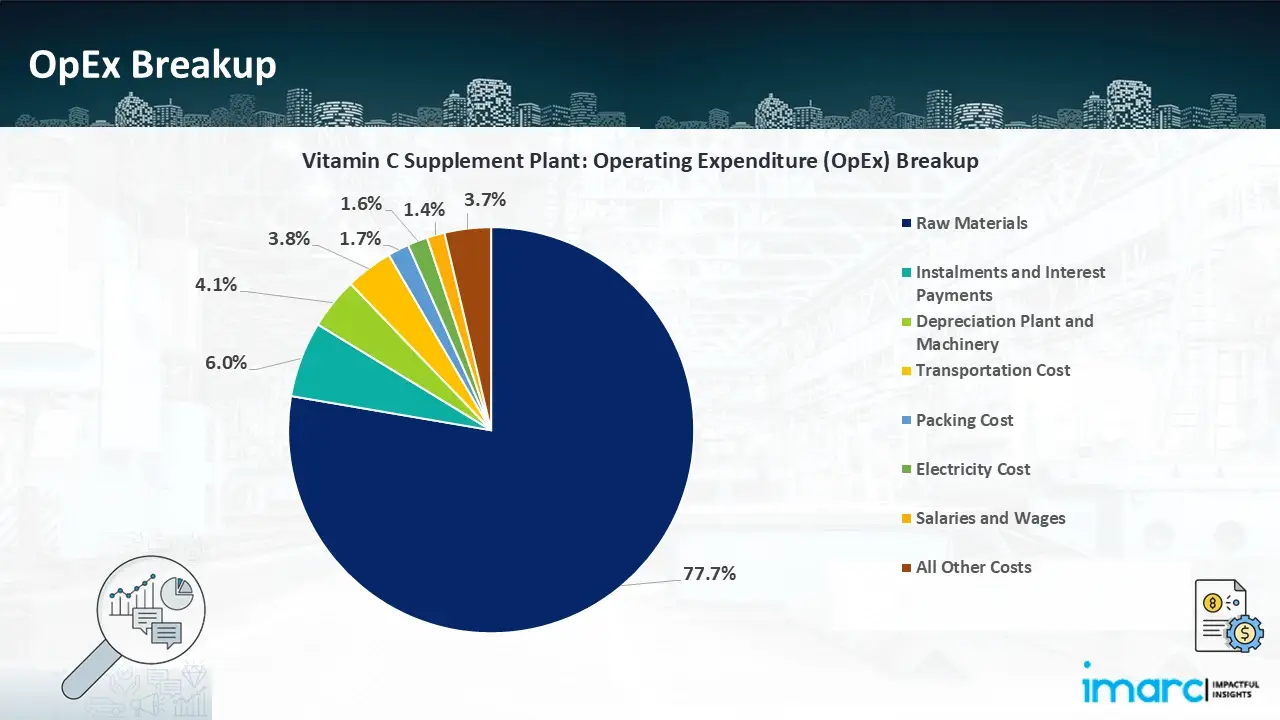

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

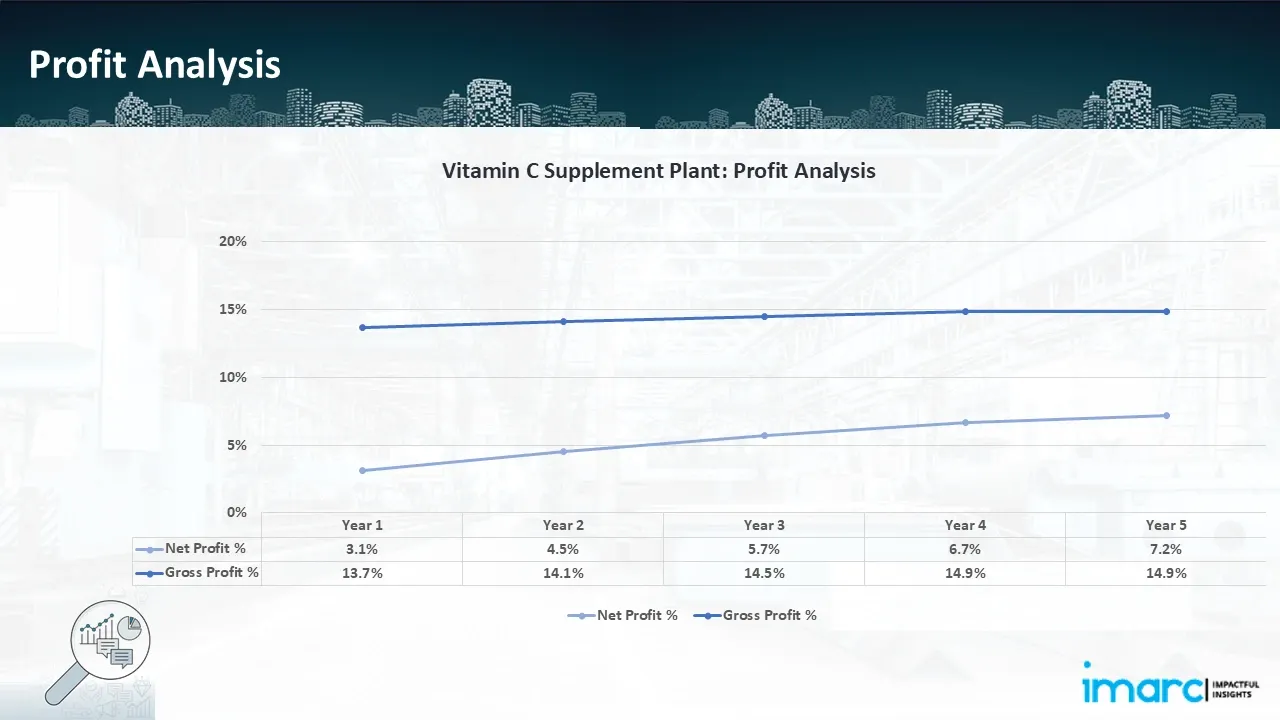

- Profitability Analysis Year on Year Basis: The proposed vitamin C supplement plant, with a capacity of 60 tons of Vitamin C supplement per day, achieved an impressive revenue of US$ 35.63 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 13.7% to 14.9%, and net profit rise from 3.1% to 7.2%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our vitamin C supplement manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 60 tons of vitamin C supplement per day. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In October 2024, Slovenian brand Ars Pharmae d.o.o. introduced BetaCold Amino, an immune-boosting supplement combining 250 mg of Wellmune, 100 mg of vitamin C, 15 mg of zinc, and 10 µg of vitamin D.

- In April 2024, Naturacare announced that it will exhibit its complete production capabilities at Vitafoods Europe 2024 and introduce four new products. Magnesium, vitamins B2, B6, B12, and C, and electrolytes are among the four products.

- In August 2023, Nutritional Research Company, a US supplier of vitamins, minerals, and supplements introduced a supplement line for three patented blends of vitamin C and D3—1000 international units (IU) and 2000 IU.

- In June 2022, P&G has launched its VÖOST brand of effervescent vitamin and mineral supplements nationwide in the U.S. The brand offers a range of products designed to support immunity, hydration, and overall wellness. This expansion aligns with P&G's strategy to strengthen its presence in the health and wellness sector.

- In June 2021, Cipla Health expanded its line of products in the health and wellness sector with the introduction of the Maxirich Gold Supplement and Maxirich Vitamin C Chewable Tablets. The vitamin C tablets are intended to increase immunity, while Maxirich Gold is a high-end supplement intended to promote general health and vigour. This launch is in line with Cipla Health's plan to solidify its place in India's expanding nutraceuticals sector.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104